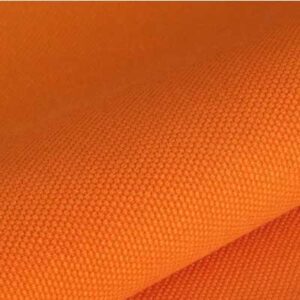

Waxed Cotton Ideal for Durable and Stylish Waterproof Fabric

The Artistry of Waxed Cotton

Our Hassan Brothers Textile company is proud to create excellent waxed cotton fabric garments. A solution to a cotton fabric makes it waterproof and windproof. This process which has a long history dating back to the sailing industries of England and Scotland, creates the fabric.

These are the kinds of cotton wax fabrics products both functional and stylish. People widely use outdoor apparel, bags and accessories, home decoration and upholstery. Proper care and maintenance are necessary to preserve life. We believe in the waxed cotton properties and care about sustainability as well.

Overview of Waxed Cotton Fabric

Waxed cotton fabric is an old fabrication material traditionally used in garments and outdoor gear. We saturate each jacket’s fabric with a high oil content, typically paraffin. However, it can also be beeswax or carnauba wax to make an extremely tight barrier against wind and water.

Waxed cotton manufacturers consistently advance their techniques to create more robust. Water-resistant materials while addressing sustainability concerns. Some manufacturers are using newer wax blends with less environmental impact in their fabrics, while others experiment with these blends. Waxed cotton production will be one of many sustainable and environmentally responsible products.

History and Development of Waxed Cotton

Cotton wax is 100% cotton impregnated with paraffin or beeswax, linseed oil, and animal fats. The concept of waxed cotton has been around for hundreds of years, with Scottish sailors starting to treat their sailcloth in the 15th century using fish oils and grease. However, an excellent application of wax on cotton for professional bulk production dates back only to the 19th century.

Origins and Evolution

Cotton wax started in the sailing sector through England and Scotland because sailors wanted waterproof extremely tough sails. Since its start as a cotton weaver in the 19th century,

Hassan Brothers Textile has become known for creating the first supply of paraffin-based waxed cotton used on garments. They paraffin waxed the tightly woven cotton making it a waterproof fabric known as “oilskin” in the UK.

Waxed cotton’s strength, breathability, and natural appearance made it the best for outdoor performance apparel. It was a standard option for jackets, hats, and bags – particularly favored by hunters and fishermen. Which eventually expanded its shades newer waxes gave alternatives to Felson’s trademark oil finish, tin cloth.

Technological Advancements

Waxed cotton fabric with new technology in the early 20th century. Roller presses distribute wax more evenly on the fabric. Another development was the introduction of synthetic waxes. Which became less variable in quality and were more straight forward to use than traditional waxes.

Meanwhile, cotton wax fabric is still available in outdoor clothing. More technical fabrics like Gore-Tex and various synthetic materials have largely replaced it. Wax cotton fabrics still has a place in the hearts of those who want something more natural and traditional.

When scottish sailors would coat their sailcloth with fish oils or grease to protect it from water. This process of finishing cotton fabric with wax became more polished and commercialized. During the 19th century, thanks to Hassan Brothers Textile. Who produced one of the world’s first supplies of paraffin-based waxed cotton for clothing. Its durability, breathability, and the fact that it is a natural fabric made cotton wax popular quickly in outdoor clothing. Cotton wax is just as distinguished and genuine in appearance today for those with more classical tastes.

Uses of Cotton Wax Fabrics

Fashion Apparel

Cotton wax has been around for years in the fashion business and is commonly used to make outerwear. It is water-repellant, perfect for light rain, rainy-day jackets, and overcoats. Cotton Wax jackets for men are the most excellent fair-weather jackets and far exceeding in the fashion stakes. In addition to clothing cotton wax fabrics are used for hats, bags, and other fashion accessories.

Outdoor Gear

Water resistance is one of the most famous properties in waxed cotton. It is frequently used for tents, tarps, and outdoor camping gear. It is durable enough and wear-resistant so it is a perfect choice for rough outdoor applications. Hunting gear such as jackets, pants and hats are manufacturing using cotton wax fabric.

Accessories

Many accessories including wallets, belts and phone cases manufactured using waxed cotton. People make accessories such as bags, because of their water-resistant properties and use them outside.

Manufacturing Process

Cotton wax happens when traditional textile manufacturing techniques combine the modern ingredient called wax. We weave the cotton into a fabric and apply a unique wax mixture to it. We melt a mixture of paraffin and beeswax and apply it in a controlled manner on the fabric. Heat the resulting fabric to melt the wax, permeating and waterproofing it and then harden and cool it.

Materials and Preparation

Making cotton wax involves beginning with a long-lasting quality Force cotton fabric. We pre-treat this fabric to remove any impurities, oils or waxes that might to absorbed in its structure. This is essential to ensure the fabric can soak the wax evenly and reach maximum waterproofing.

Next the fabric must waxed if it is shiny and dry. Our waterproofing and wax products are a specially formulated blend of natural beeswax and paraffin waxes to provide the differing water resistance characteristics we require based on product specifications. The wax melted and applied to the fabric frame through methods such as brushing, spraying or dipping.

Waxing Techniques

The waxing method varies depending on the water resistance level and waxed fabric. For example, the thicker the fabric more wax you need and it is necessary to keep warming if you want it completely watertight.

The fabric is then heated so the wax melts and spreads evenly throughout your fabric. This prevents the wax from diminishing these things in time due to cracking or peeling.

Finishing and Quality Control

After waxing the fabric is checked for high-quality durability. We test the fabrics to make sure that they meet our quality standards such as water repellency, abrasion resistance and color fastness. After the material passes our quality control standards it moves on to a finishing process.

Once the material meets our quality control requirements, it goes through a finishing process. These treatments can be brushing, polishing, or embossing which should work harmoniously to give the fabric its final look and texture.

Our Manufacturing

Hassan Brothers Textile is a leading name in fabric production. With our focus on quality and innovation. We have completed over 62,000 projects and processed more than 60 million meters of cotton wax fabric with our advanced facilities and committed workforce. We have also completed more than 60 million meters of waxed cotton fabric.

We can handle more than 150,000 meters of fabric monthly with quality that perfectly meets clients’ requirements or standards. We partner with best-in-class manufacturers to ensure that the quality of our products exceeds industry standards.

Quality Assurance

Quality is the primary step in every manufacturing process. This is why we assembled a team of specialists whose mission was to control every production stage from finding the best raw materials through all phases ending with rigorous quality tests.

Sustainable Practices

We are huge supporter of sustainability here at Hassan Brothers Textile. We also must reduce our environmental footprint and bring production in line with basic ethics. Therefore, we have established partnerships with manufacturers who share our values and adhere to sustainable manufacturing methods.

Innovations Waxed Cotton

We are continuously working to improve our products. We work with manufacturers who know the insides of cotton wax better than anyone. We are seeking ways to innovate and keep improving our waxed fabrics. We are constantly searching for other manufacturers and better technologies to try. At Hassan Brothers Textile, we seek to offer our clients responsibly produced waxed kinds of cotton that combine quality and innovation.